Tomobe Plant

1320-5, Nagatoro, Kasama City, Ibaraki Prefecture, 309-1712 Japan

Telephone:(Main)+81-296-77-8888 (Sales)+81-296-77-8804

FAX: (Main)+81-296-77-8901 (Sales)+81-0296-77-8849

Management philosophy is a concept that serves as the basis of action policy for all the businesses of the Air Water Group.

The origins of the AIR Water Group’s business can be found in its name, which consists of two words: “air” and “water.”

We make use of the resources of our precious earth to create businesses and contribute to society and everyday life.

Amid a business environment that continues to change at a dizzying pace, we will continue to leverage the Group’s collective capacities to tackle problems faced by our customers and society, and will rise to the challenge of creating new value.

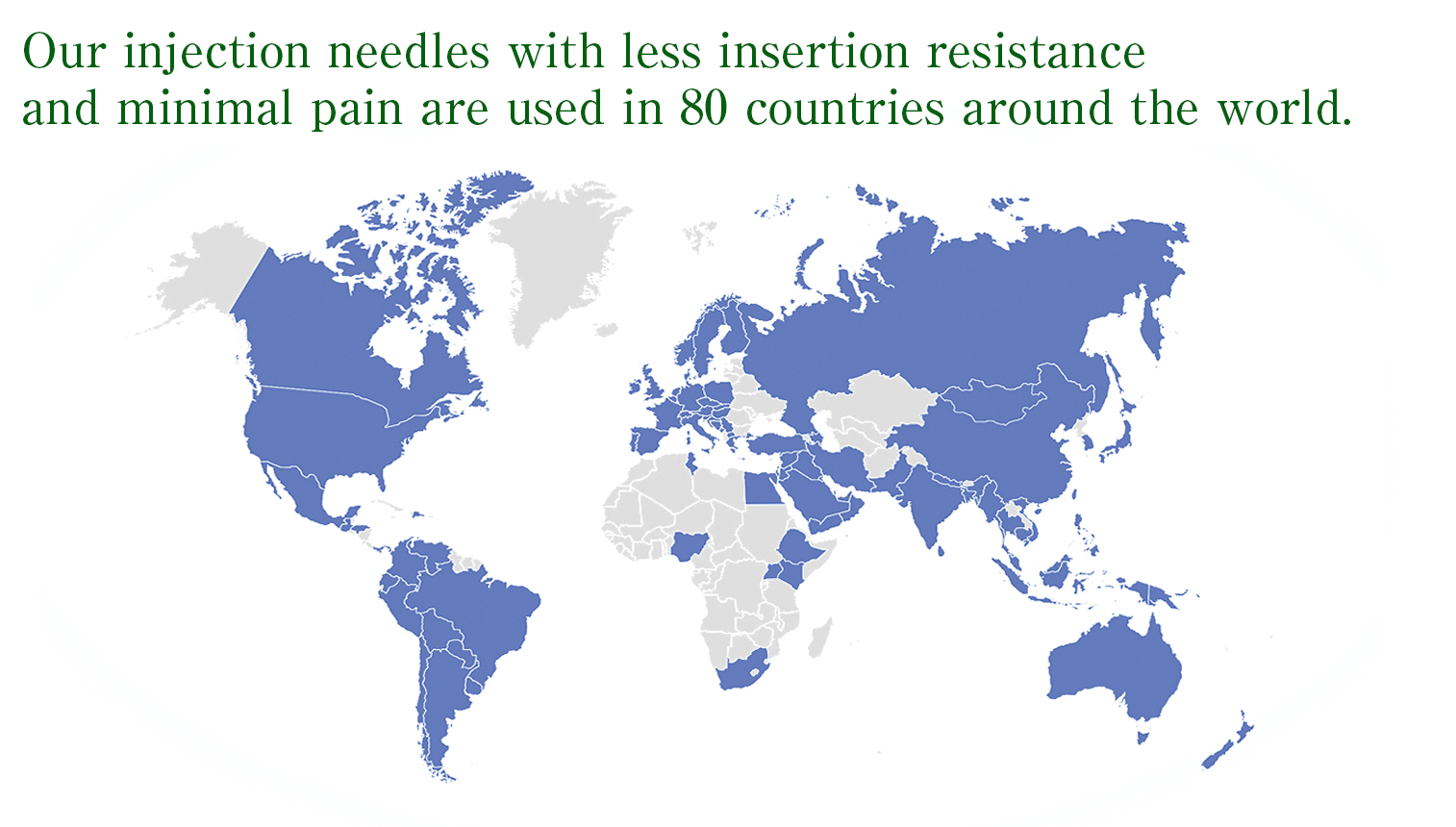

Currently, we are delivering the injection needles we produce to markets in more than 80 countries around the world.

As we have strived for over 50 years to produce injection needles and other essential medical hardware, our goal has been to create “Painless Needles.” In other words, we wish to minimize the pain of patients.

To achieve this goal, however, we have had to assemble advanced technologies, to diligently tackle daily production tasks, and to maintain a constant commitment to enhancing quality. As the fruit of this approach, our injection needles are now used in over 80 countries around the world, a fact that gives us a great sense of pride.

Now, with the advanced technology and sophisticated production system we have set up, we can look ahead with an even broader mission for the future—to develop new products and make further contributions to the field of medicine.

We have relocated our plant from Asahi machi to Nagatoro, Ibaraki central industrial park in Kasama City. We will introduce new production facilities for injection needles in dental and aesthetic field. Apart from expanding the advanced medical product facility for injection needles with 2 high-class clean rooms, we will strengthen further production capacity with our existing plants. This change enable us to increase the annual production capacity at 3 domestic plants from 1.9 billion pcs to 3 billion pcs. Our mission is to respond the growing demand for Japanese high quality needles in overseas. In order for us to achieve customer’s needs, we will continuously establish production and development system to provide higher performance, and higher quality products efficiently.

| Location | 1320-5, Nagatoro, Kasama City, Ibaraki Prefecture, 309-1712 Japan Telephone:(Main)+81-296-77-8888 (Sales)+81-296-77-8804 FAX: (Main)+81-296-77-8901 (Sales)+81-0296-77-8849 |

|---|---|

| Area | Site area: 22,000㎡ Total floor space:3,947㎡ |

| Floor | 1 floor, steel framed structure |

| Manufacturing categories | Hypodermic Injection Needles, Dental Needles, Aesthetic Needles |

| Production capacity | 1.9 billion pcs/ year |

| Introduction equipment | Needle assembling machine (for dental and aesthetic), 2 clean rooms (Assembling lines: class 10,000 835㎡, Molding lines: class 100,000 647㎡) EOG (Ethylene oxide gas) sterilization devices |

| Number of employees | 98 employees |

| Operation start date | June 15th of 2020 |

| Main Business contents | Manufacture, sale, import and export of sterilized medical equipment |

|---|---|

| Main exporting country | United States, Canada, Colombia, Brazil, Mexico, United Kingdom, Germany, Italy, France, Saudi Arabia, Egypt, Nigeria, South Africa, China, Vietnam, Thailand, Taiwan, Indonesia and Australia Additionally,80 countries in the world. |

| Number of Employees | 318 |

| Joining group | THE TOKYO CHAMBER OF COMMERCE AND INDUSTRY, Japan External Trade Organization(JETRO), Eastern Japan plastic industrial society, Medical Technology Association of Japan (MTJAPAN) |

| 1956 | Established plastic blow molding plant in Sumida-ku, Tokyo. Commenced plastic blow molding production. |

|---|---|

| 1963 | Moved from Sumida-ku, Tokyo to Hirai, Edogawa-ku, Tokyo, and increased production with injection molding machines. Succeeded in developing plastic cases for injection needles (patent acquired), and commenced manufacture of medical equipment. |

| 1965 | Succeeded in manufacture of disposable injection needles. New plant established in Minamihara, Tomobe-machi, Nishi-Ibaraki-gun, in Ibaraki Prefecture, and full-scale production of injection needles commenced. |

| 1972 | Company name changed to Misawa Medical Industry Co., Ltd. New plant completed at Asahidai. |

| 1986 | Head Office building completed in Hirai, Edogawa-ku, Tokyo. Relevant authorities notified of medical equipment sales operations. |

| 1987 | New plant complex constructed at Yoshima Industrial Park in Iwaki City, Fukushima Prefecture, and operation commenced. |

| 1994 | Shanghai Misawa Medical Industry Co., Ltd. joint venture company established in Shanghai, China. |

| 1994 | Licensed for manufacture of medical equipment for animals. |

| 1998 | Acquired the ISO 9001 international certification for quality management and quality assurance. |

| 1999 | Acquired sterilization process manufacturing category permission, and commenced contracted sterilization operations. |

| 2004 | Acquired ISO 13485:2003 quality certification for medical equipment. |

| 2012 | Head Office General Affairs and Sales Department consolidated at Asahidai Plant in Kasama City, Ibaraki Prefecture. |

| 2012 | Tokyo sales office (Hongo) opened. |

| 2016 | Transfer of all shares to Air Water Inc. and Kaigen Pharma Co., Ltd. |

| 2018 | Merged with Saito Medical Industries, Inc. |

| 2019 | Became a wholly owned subsidiary Air Water Inc |

| 2020 | Main factory completed in Ibaraki Central Industrial Park (Kasama area) , and the head office and Asahidai plant relocated. |

| 2021 | Merged with Matsuoka Meditech Corp. and The name of the plant has changed (Head office & plant ⇒Tomobe Plant / Saito Plant⇒ Nasu Plant) |

| 2023 | Fuji Giken Kogyo Co., Ltd. Business transfer (Fuji Factory: Former Atsuhara Factory, Fujinomiya Factory: Former Kamiide Factory) |

| 2023 | Air Water Realize Inc. merged Misawa Medical Industry Co., Ltd. |

1320-5, Nagatoro, Kasama City, Ibaraki Prefecture, 309-1712 Japan

Telephone:(Main)+81-296-77-8888 (Sales)+81-296-77-8804

FAX: (Main)+81-296-77-8901 (Sales)+81-0296-77-8849

767-80 Hachisu, Ohtawara City, Tochigi Prefecture 324-0244, Japan

Telephone:+81-287-54-0546

FAX: +81-287-54-3517

21 Yoshima-Industrial Park, Iwaki City, Fukushima Prefecture 970-1144, Japan

Telephone:+81-246-36-6870

FAX: +81-246-36-6871

1602 Atsuhara, Fuji City, Shizuoka Prefecture 419-0201, Japan

Telephone:+81-545-71-1990

FAX: +81-545-71-1991

2151-2 Kamiide, Fuji City, Shizuoka Prefecture 418-0103, Japan

Telephone:+81-544-54-3125

FAX: +81-544-54-3100

| License and qualification | Plant | The permission number |

|---|---|---|

| 2nd-class medical devices marketing license | Tomobe Plant | 08B2X10007 |

| 2nd-class Animal medical device manufacturing and sales license | Tomobe Plant | 30製販療Ⅱ第65号 |

| Medical equipment manufacturing industry registered | Tomobe Plant | 08BZ200116 |

| Iwaki Plant | 07BZ000081 | |

| Asahi-dai Plant | 08BZ000108 | |

| Animal medical device manufacturing license | Tomobe Plant |

2製造療第647号 |

| Asahi-dai Plant | 29製造療第79号 | |

| Medical devices sales license | Asahi-dai Plant | 笠第344号 |

| EC Directive 93/42/EEC | Tomobe Plant Iwaki Plant Asahi-dai Plant |

HD 2014410-1 |

| EN ISO 13485:2016 | Tomobe Plant Iwaki Plant Nasu Plant Asahi-dai Plant |

SX 2014410-1 | FDA | Tomobe Plant | 3017024395 |

| Iwaki Plant | 9612124 | |

| Asahi-dai Plant | 9612129 |